This week, we talk High Temperature Gas Reactors, or HTGRs, with a Decouple favorite: reactor designer and nuclear historian Nick Touran (What Is Nuclear | X). From the first conceptual sketch of an HTGR in wartime labs to today’s revival by players like X-energy and China’s fast-moving reactor fleet, we dissect what makes HTGRs unique—both in engineering promise and the difficulties that have long haunted their success. With helium cooling, TRISO fuel, and ambitions beyond electricity into process heat and industrial decarbonization, HTGRs may be poised for a comeback. But will history repeat itself, or finally break the cycle?

Watch now on YouTube.

We Talk About

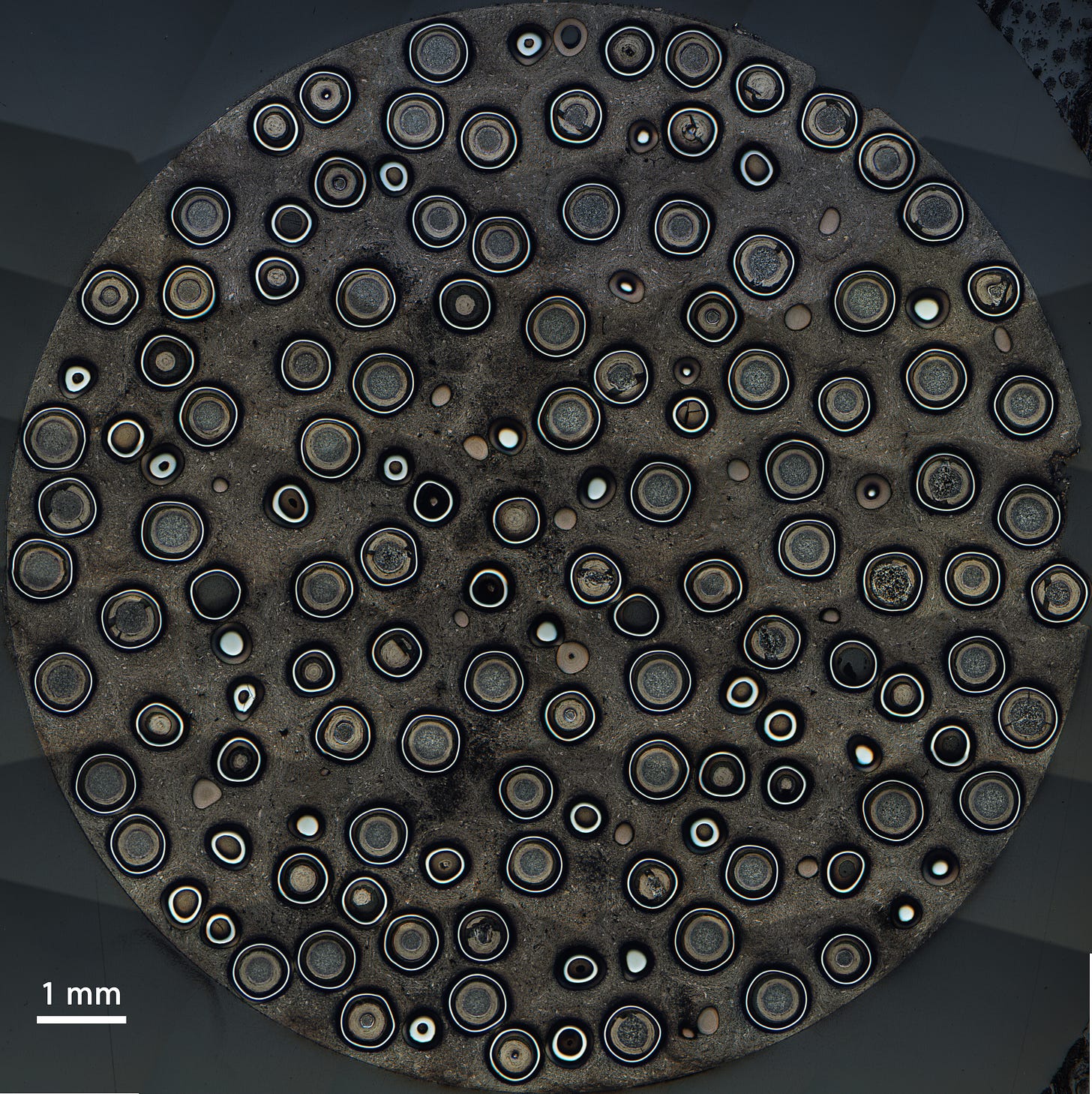

Technical fundamentals: helium cooling, graphite moderation, and TRISO particle fuel.

Early idea: Farrington Daniels' starting vision and the post-Manhattan Project birth of the gas-cooled concept.

Example reactors: Dragon in the UK, Peach Bottom and Fort St. Vrain in the US, and the AVR and THTR in Germany.

Economic troubles: Why early reactors, despite functional success, struggled to compete economically with large-scale LWRs.

Operational troubles: helium purification, water ingress, stress corrosion, and instrumentation fragility.

Scaling troubles: the overly ambitious Fort St. Vrain and THTR reactors and the lessons of premature scaling.

Modern deals, like X-energy’s collaboration with Dow and Amazon’s investment.

China’s rollout of HTR-PM reactors, complete with six-packs and centralized process heat applications.

TRISO fabrication challenges and the need for HALEU fuel; cost implications and scaling strategies.

The promise of HTGRs for decarbonizing process heat across sectors: oil refining, hydrogen, and steel.

Potential for modularity and design simplification to solve historical obstacles.

Deeper Dive

High-temperature gas reactors are, in many ways, like a recurring dream. They’ve been imagined, built, decommissioned, forgotten, and revived more times than most other reactor types. From their early beginnings under Farrington Daniels—who envisioned a pebble-bed reactor driving a helium gas turbine without steam as an intermediary—they’ve always held the promise of elegance and efficiency. Daniels, a chemist by trade, wasn’t just tinkering; he laid the blueprint for what could eventually be a workhorse for industrial heat and flexible power.

And yet the history of HTGRs has been the story of ambition colliding with economic and engineering reality. Pennsylvania’s Peach Bottom Unit 1, an experiment helium-cooled graphite-moderated reactor that turned on in the late 1960s, ran clean and steady for its short life. Its capacity factor, hovering near 90%, was among the best for any reactor of its time. But next to the hulking output of the site’s 2nd and 3rd unit, both more-than-gigawatt boiling water reactors, it seemed quaint—too small to matter. Its fuel was innovative, but its cost per kilowatt-hour couldn’t compete. The lesson was clear: in nuclear, scale matters.

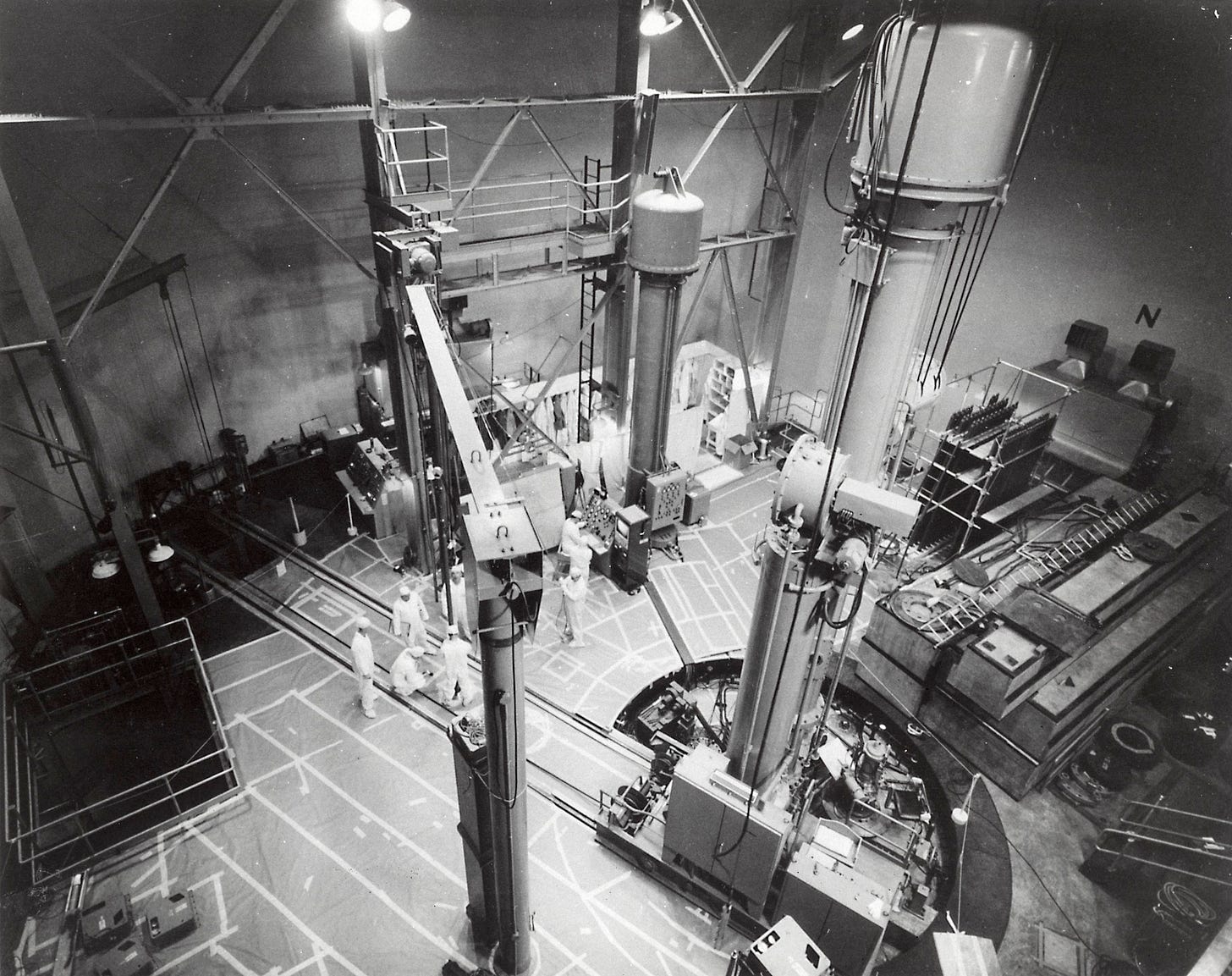

Fort St. Vrain in Colorado took the opposite route. It was a good deal larger than Peach Bottom, up to the size of modern SMRs—330 MW and housed inside a pre-stressed concrete vessel five meters thick. But with its bulk it lacked grace. Plagued by persistent failures—water ingress, faulty sensors, rusted control rods—it became a cautionary tale of overengineering. The promise of HTGRs turned, once again, into a reminder of nuclear's unforgiving learning curve.

“Fort St. Vrain became a symbol of engineering overreach—too big, too complicated, too unreliable.” –Nick Touran

Germany offered another chapter in the HTGR saga, one shaped by the AVR and its larger cousin, the THTR. Using pebble-bed technology, these reactors introduced new operational insights, and new headaches. Control rods accidentally crushed fuel pebbles. Tritium leaked. Post-Chernobyl, any misstep, no matter how minor, became politically fatal. THTR hit full power just months before Chernobyl, and shut down again within two years.

“Reliability and economics are two different virtues—and HTGRs have yet to prove they can marry the two.” –Nick Touran

And then there's China—a country that, in contrast to the seemingly cautious West, has gone all-in on HTGRs. The HTR-PM project reflects this confidence. Instead of scaling a single reactor, they’re building clusters—six-packs of HTGRs feeding shared turbines, with centralized fuel handling and process heat off-take. The revolver-like layout isn’t just visually clever—it’s a logistical masterstroke. Their approach suggests that modularity, not size, might be the key to commercial viability amid the scaling troubles of HTGRs.

“People say, ‘we better make reactors now because we might fall behind China.’ But look at what China is doing. We are way behind. We are 20 years behind. It’s blatantly obvious when you look at what they're operating.” –Nick Touran

How shall we fuel these reactors? TRISO fuel, while robust and meltdown-proof, remains expensive to fabricate. It requires HALEU—or medium-enriched uranium—which adds another layer of regulatory and supply chain complexity. Can the costs be driven down? Will the next generation of fabricators deliver on scale? These questions linger. China seems to think the answer is yes.

If economically viable, these reactors promise more than just electricity. Process heat remains the great frontier. Dow wants it, as shown by its partnership with X-energy. Refineries need high temperature heat. Hydrogen and synthetic fuels also demand it. And HTGRs might be the only nuclear path to delivering it directly and efficiently. Process heat might be the real proving ground for this technology.

Underlying it all is a geopolitical wrinkle. China’s nuclear momentum unfolds behind a wall that the West shows little interest in peering behind. Lessons learned at Dragon, Peach Bottom, and Fort St. Vrain echo now in Shidao Bay, but the lines of communication are fraying. The open exchange that once defined global nuclear innovation has faltered. In a field that advances by sharing—and by learning from failure—that silence is costly.

The HTGR remains an unfinished project, and perhaps that’s what keeps it interesting. It's not just a technology; it’s a mirror of our ambitions, our caution, and our capacity to learn.

That’s all for this week. We strive to bring you energy literacy on demand, without sacrificing on expert detail. Please consider supporting our work by pledging on Substack or making a tax-deductible donation through our fiscal sponsor. Thank you!

Timestamps

00:00 Introduction

02:31 HTGR Basics

06:21 Low-temperature Gas Reactors

07:53 Farrington Daniels' brainchild

13:54 Why HTGRs are interesting

24:57 HTGRs in history

35:44 Technical challenges

43:33 The importance of just building

45:26 German HTGRs

51:28 Chinese HTGRs

55:24 Reactor lifespans

58:03 Process heat

1:07:09 Fuel challenges

1:10:08 The future of HTGRs: China v. the West

Keywords

High-temperature gas reactor, HTGR, TRISO fuel, helium cooling, nuclear process heat, Peach Bottom, Fort St. Vrain, AVR reactor, China, HTR-PM, nuclear modularity, thorium fuel cycle

Share this post