Nick Touran, a nuclear engineer and manager at TerraPower, unearths the sobering realities of micro nuclear reactors. Through a detailed discussion of physics, engineering, economics, and history, Touran explains why microreactors face fundamental challenges that factory production alone cannot solve.

Watch now on YouTube, Spotify, and Apple.

We talk about

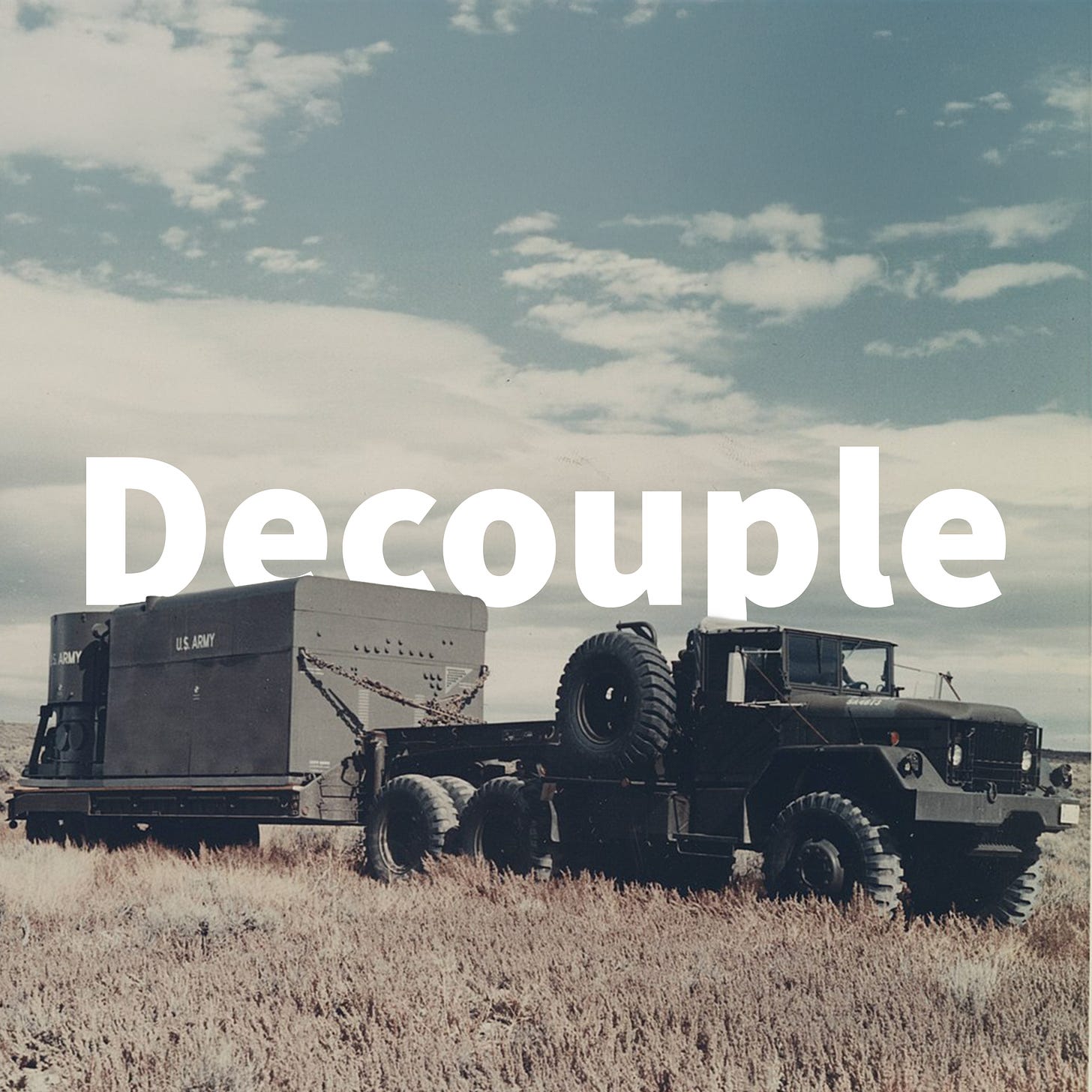

Historical microreactor programs, especially for military applications

Physics of nuclear shielding and neutron economy, and the often-ignored burdens these impose on microreactors

Heat pipe technology and passive safety systems

Economics of microreactor fuel cycles, HALEU (medium-enriched uranium), and TRISO fuel

Challenges of spent fuel handling and maintenance

Steep regulatory and licensing requirements

Modern microreactor designs and proposals

"Even if the reactors are free, if the fuel cost is still absurd, you have no solution."

— Nick Touran

Some takeaways

Microreactors face fundamental physics constraints related to neutron economy compared to larger reactors that cannot be solved by manufacturing improvements alone

High fuel costs, especially for medium-enriched uranium and TRISO fuel, present major economic challenges that all but relegate microreactors to niche applications

Substantial and underestimated shielding requirements make micro reactors fundamentally different from diesel generators

"You will never be able to make a neutronically efficient, tiny reactor that, if you just build a bunch of them, is cheap… That is a key fundamental neutronics issue. I don't care how many factories and how much modularization you've done. You're not getting around that.”

— Nick Touran

Deeper Dive

The road to microreactors for niche use cases will not be easy. Just a 2-kilowatt reactor requires approximately 5 feet of concrete shielding, with radiation levels that could deliver fatal doses within seconds if unshielded. Heat pipe reactors like eVinci require roughly 1,000 heat pipes arranged between fuel elements for heat transfer, resulting in potential operational and maintenance headaches. As for fuel, current HALEU fuel costs are estimated at $20,000-30,000 per kilogram, compared to $300 per kilogram for conventional LEU fuel fabrication, meaning microreactors that use HALEU might not be competitive even if the reactor were free. Nor does the small size of microreactors mean they have will have minimal staffing requirements: the Army's PM-1 reactor, for example, required 25 full-time staff and still experienced 40 unplanned outages, further highlighting maintenance challenges.

Learning from these experiences with microreactors, rather than minimizing them, is mandatory if we are to make progress on tiny nuclear reactors.

The “Camp Century” documentary that Touran mentions 20 minutes in:

Watch other fascinating early documentaries on nuclear power digitized by Touran here. Visit Touran’s whatisnuclear.com.

Timestamps

00:00 Visions for microreactors

03:49 Defining microreactors

11:56 The problem of radiation shielding

18:48 Original microreactor projects

24:29 Niche applications

30:32 The problem of neutron economy

40:08 The problem of fuel

53:03 The problem of operations and maintenance

1:00:17 The problem of commercialization

1:05:42 The problem of spent fuel

1:09:27 The problem of scaling

1:12:36 The problem of licensing

1:13:42 Hope for microreactors

1:15:18 Scaling down reactors with LEU?

1:21:50 Recap

Keywords

micro reactors, nuclear power, HALEU fuel, heat pipe reactors, nuclear shielding, Army Nuclear Power Program, TRISO fuel, small modular reactors, passive safety systems, nuclear economics, eVinci reactor, nuclear fuel cycle

Share this post