Welcome to Decouple, the best source for cutting-edge analysis on nuclear energy, with weekly expert interviews by . See our testimonials. Watch on YouTube, Spotify, or Apple. Read on for a summary of this week’s episode.

This week, Jeff Waksman, program manager for Project Pele, joins me to discuss the impetus for the U.S. military microreactor project, the logistics and energy challenges at the heart of modern warfare, and the technical considerations of mobile microreactor development. Few voices are more qualified to speak on the state-of-the-art in tiny nuclear reactors.

Watch the full interview on YouTube.

About the guest

Jeff Waksman serves as Program Manager at the Strategic Capabilities Office (SCO) within the Office of the Secretary of Defense, where he leads Project Pele and Project TRISO. In addition to working at the Department of Defense, his career spans work at NASA, IBM, the U.S. Congress, and various roles in the executive branch. Waksman holds a PhD in physics and a master's degree in nuclear engineering.

In a nutshell

Project Pele is the Department of Defense's ambitious program to develop a transportable microreactor that can deliver 1-5 megawatts of electrical power for military purposes, designed to fit within four 20-foot shipping containers, capable of being transported by truck to remote or strategic locations. The project represents the most advanced microreactor development effort in the U.S., with hardware already being manufactured and assembly planned to begin in early 2025.

"If you think nuclear is going to be easier than it really is, it will lead you to bad policy decisions where you will attempt things that are more likely to fail."

– Jeff Waksman, Project Pele Program Manager

We talk about

The strategic rationale for military microreactors

Technical details and challenges of Project Pele's design

Historical context of military nuclear power programs like the Army Nuclear Power Program

Logistics and energy security in modern warfare

Practical challenges of microreactor development

Shielding and maintenance considerations

International developments in military nuclear power

Some takeaways

Modern warfare's increasing dependence on reliable power and airtight logistics makes nuclear an attractive alternative to fossil fuels

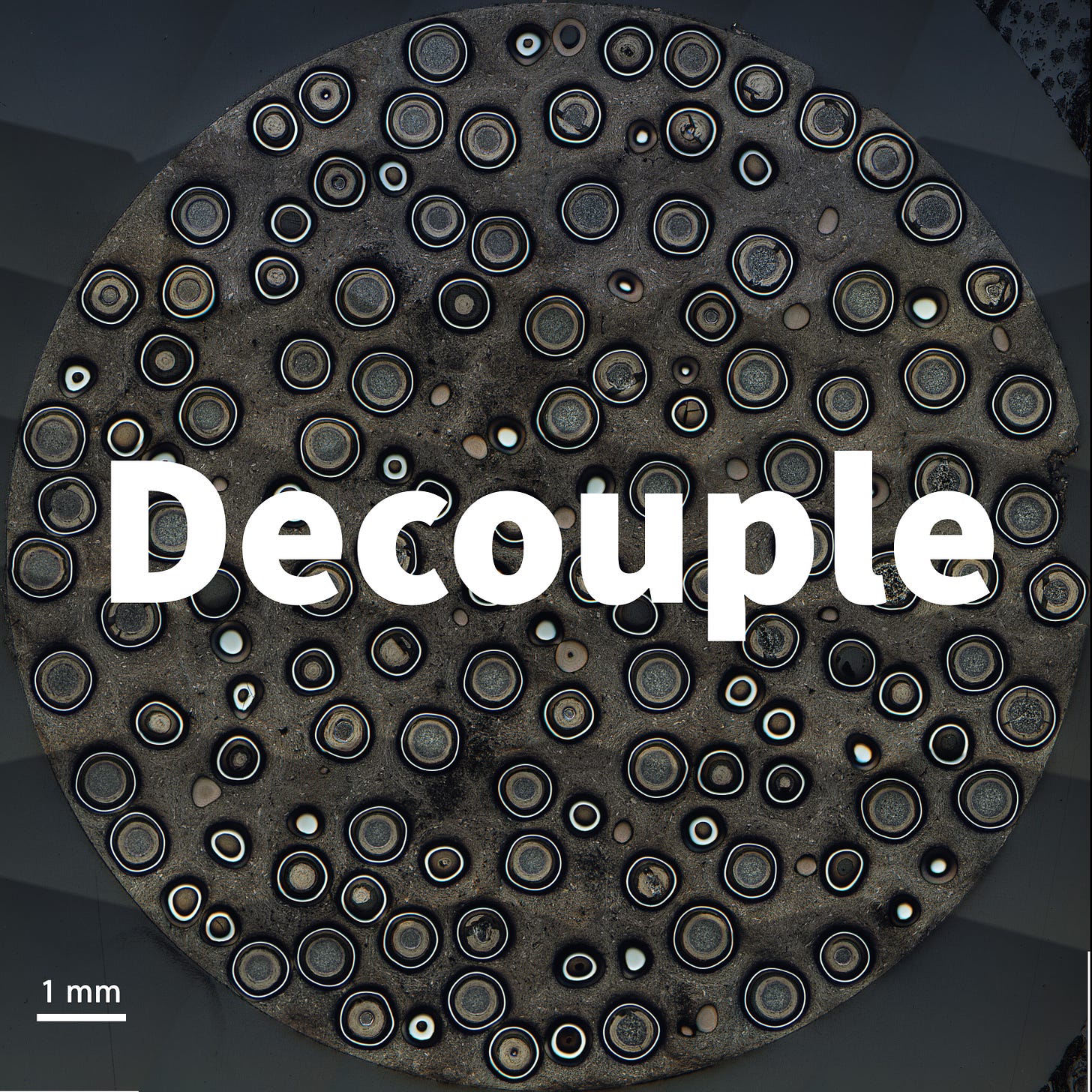

Project Pele uses TRISO fuel and an open Brayton cycle design, prioritizing proven technology over novel concepts. The contract for the design went to BWXT, who is pursuing a High-Temperature Gas Reactor design

Thermal stress management has emerged as one of the biggest engineering challenges, particularly in small designs that offer much less space in which to cool the reactor

Microreactors face inherent challenges with economies of scale but can be viable in locations already paying high electricity prices

First-of-kind reactors should not be expected to achieve the high reliability of mature technologies immediately

Waksman values rigorous testing and realistic expectations over optimistic promises

"In warfare, amateurs study tactics and professionals study logistics."

– Jeff Waksman, Project Pele Program Manager

Deeper Dive

Project Pele represents a significant departure from recent nuclear reactor development—in Wakman’s words, “resurrecting defense nuclear from a place it hasn’t been at since the 60s.” The High-Temperature Gas Reactor system consists of four 20-foot shipping containers: one housing the reactor, another containing the intermediate heat exchanger, a third holding the power conversion turbine, and a fourth serving as the operating module located 200 yards away. The reactor uses TRISO fuel enriched to 19.75% and employs an open Brayton cycle with air as the secondary coolant.

The program has faced unique engineering challenges, particularly in managing thermal stresses. Waksman revealed that existing ASME codes proved inadequate for their temperature ranges, with some models being off by a factor of two. This discovery highlighted the importance of practical testing over theoretical modeling.

The shielding strategy involves a combination of approaches, including water-filled containers that can be emptied for transport and filled on-site. This allows the system to maintain transportability (air transport being an important criterion) while meeting radiation safety requirements. The design deliberately separates the reactor from the power conversion system to facilitate maintenance and reduce radiation exposure.

Manufacturing is already underway, with the containment vessel forged and most of the nuclear fuel produced. The project timeline calls for beginning assembly in early 2025, with fuel completion and delivery to Idaho National Laboratory expected by mid-year. The first concrete will be laid at the Idaho site during the same period.

Regarding operations, the reactor will require constant monitoring by at least two operators, despite being highly automated. This approach parallels self-driving cars, where human oversight remains necessary despite advanced automation capabilities. The project team anticipates that initial reliability will be significantly lower than the 93% capacity factors achieved by mature nuclear plants, acknowledging the learning curve inherent in first-of-kind systems.

You might like

A short documentary from the U.S. Army and Atomic Energy Commission on ML-1, the first land-based mobile nuclear reactor.

For more knowledge on the wild history of reactor development by the U.S. military, check out our recent episode with TerraPower reactor designer Nick Touran.

Keywords

military microreactor, Project Pele, nuclear power, TRISO fuel, Department of Defense, strategic capabilities, energy security, mobile nuclear reactor, military logistics, advanced nuclear technology, nuclear innovation, military energy, transportable reactor, defense nuclear program

Share this post