Koroush Shirvan, an MIT professor and consultant on recent major reports on nuclear economics, sheds light on the hidden costs of small modular reactors. Lower power densities, ballooning containment and reactor vessel sizes, worse economies of scale, and missed opportunities for cost reductions mean that SMRs may not be the panacea for nuclear that many believe them to be.

Watch now on Spotify, Apple, or YouTube.

In an picture

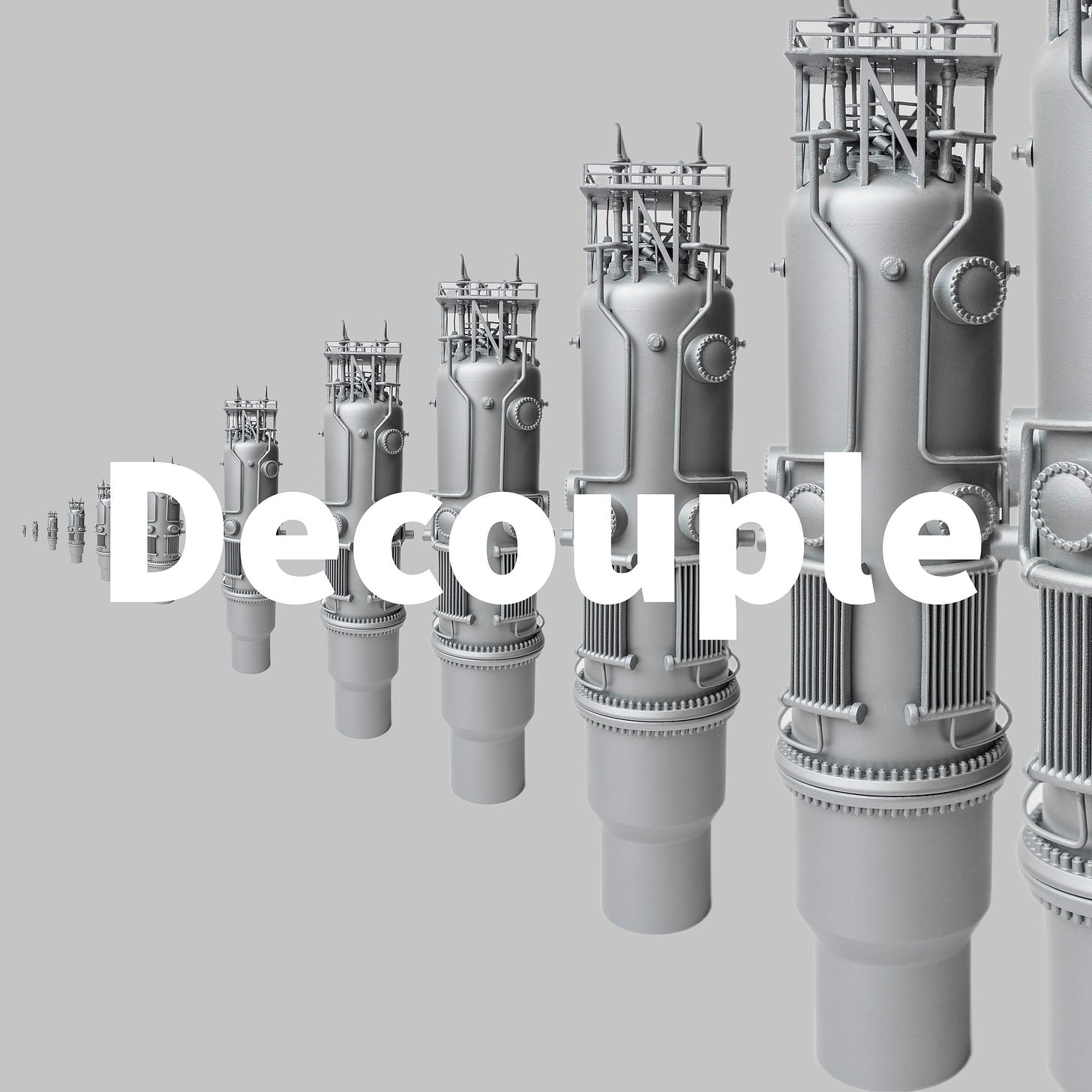

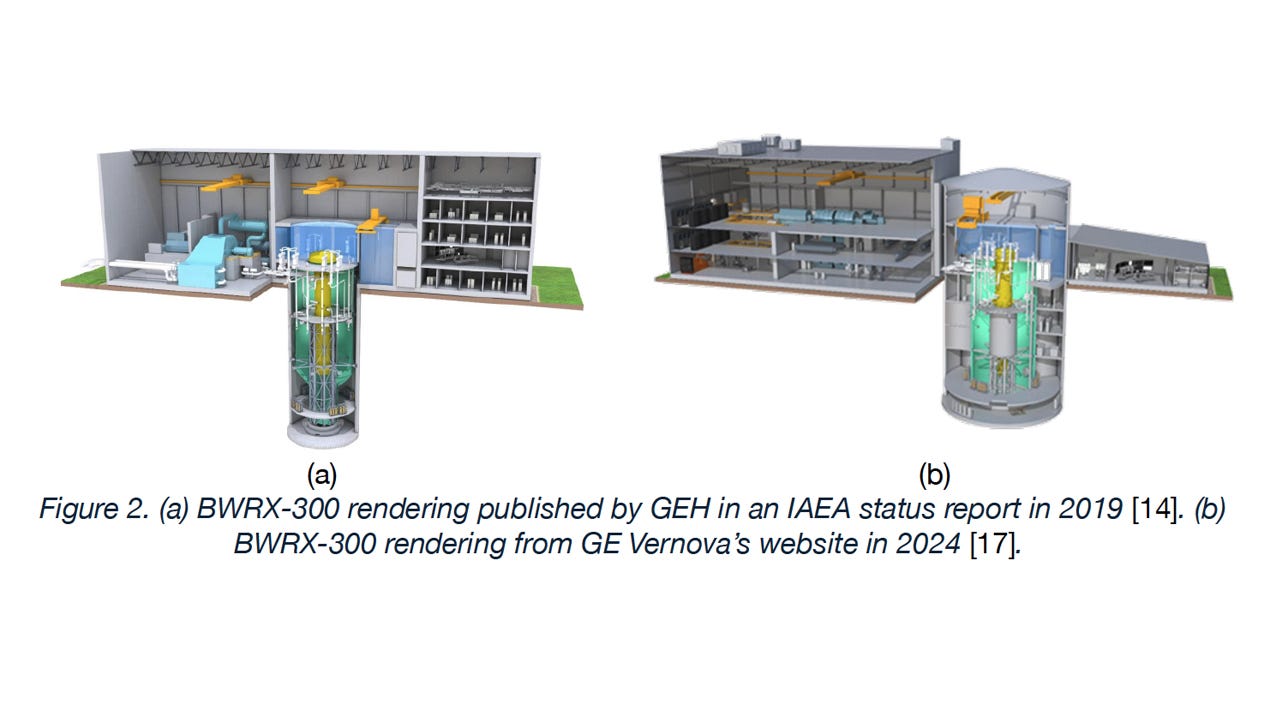

The following image shows the physical growth of the BWRX-300 SMR designs over time, from a recent paper by Alva Energy with contributions from Koroush Shirvan.

We talk about

The cracks in the original rationale for developing SMRs instead of large reactors

The growth of SMR civil works to accomodate natural circulation and the addition of safety systems after initial regulatory engagement

Learning rates and economies of scale in nuclear power plant deployment

Missed opportunities for using cost-reduction drivers, like the sharing of control rooms, turbine halls, and auxiliary systems for multi-unit plants

The role of government support and regulation in shaping the nuclear industry

Some takeaways

Large reactors offer significant economic advantages due to economies of scale and higher power densities, despite the hype around SMRs.

Natural circulation in SMRs not only lacks a safety rationale but leads to larger reactor vessel and containment sizes, driving up costs per unit of power output compared to large reactors.

Though conventional wisdom is that the bulk of nuclear reactor costs are in construction, over a reactor’s potential 60-100 year lifetime the cost of operations, maintenance, and fuel roughly equal capital costs. These costs should not be underestimated when assessing large versus small reactors.

Government support, while necessary, has at times led to prescriptive approaches that poorly align with best practices for cost-effective nuclear deployment, as seen with Canada’s SMR Action Plan.

Notable Quotes

"If you're looking at the lowest cost, of course, a large reactor would be the answer."

“When you look at the lifetime energy cost of a nuclear power plant, half of it is O&M [operations and maintenance] and fuel. It’s not 20, 10, 30 percent as people throw around.”

“It seems, based on the design documents, that [GE Hitachi] made reactionary feedback based on regulator demands [on the BWRX-300]… Now, the narrow structure that you could have buried in the ground has widened to the exact same size as the ABWR reactor building at 1350 megawatts.”

References

Evaluating Labor Needs for Fleet-Scale Deployments of Large vs.

US Department of Energy’s Pathways to Commercial Liftoff: Advanced Nuclear report

TVA’s Integrated Resource Plan

AP1000 reactor design

BWRX-300 SMR design

ABWR (Advanced Boiling Water Reactor)

ESBWR (Economic Simplified Boiling Water Reactor)

Keywords

nuclear energy, small modular reactors, SMR, large reactors, nuclear economics, passive safety, reactor design, nuclear costs, AP1000, BWRX-300, nuclear learning rates, nuclear regulation, nuclear power plant construction

The Surry Power Station has about a third of containment buried underground to answer the question ~40min in. This was done for purely cosmetic concerns of Williamsburg across the river, but it’s still a nominal 900 MWe plant. Also very interesting about the plant is their intake water canal. The plant has roughly a weeks worth of coolant water that’s fed by gravity!

Congrats Chris! The last year, since COP28, saw nuclear in steroids!

Nice work, Chris.

We have been reading Shirvan's work for several years and find it fascinating but had never heard him interviewed. Great to hear him expand on that work and discuss the TVA IRP and DOE Liftoff report as well.